Wenda Ingredients Partners with BSA Wiberg to Expand Market Presence in Canada

Announcing our new partnership to bring advanced ingredient technologies to Canadian businesses, enhancing product quality and shelf-life.

Read

The benefits of using the multi-hurdle approach.

TIMES AND TECHNOLOGIES CHANGE. So do spoilage bacteria, including both non-pathogenic and pathogenic. To defend against ever-evolving bacteria, processors and food manufacturers need to know what they are up against and how they can best protect their products. Food safety remains a top priority, as about 48 million Americans get sick from foodborne illnesses every year, according to the U.S. Centers for Disease Control (CDC).

Antimicrobials have proven to be a pivotal form of protection, going back millennia. From the first curing of fish and meat in ancient Mesopotamia to common salt curing processes in Greece in 900 B.C. to the Industrial Revolution that spawned canned foods with added sodium, antimicrobials have been espoused and used for preservation purposes.

Following the advent of synthetic ingredients such as sodium diacetate and sodium lactate in the latter half of the 20th century, there has been a return to a “less is more” approach to ingredients for natural curing and product protection. Over the past several years, consumers have embraced clean labels with pronounceable ingredients that also align with their interest in lowering their sugar and sodium intake.

Where does this leave today’s manufacturers? They must navigate the realities of frequently-mutating bacteria with simultaneous marketplace demands for safety, quality and health. It can be quite challenging to balance a variety of concerns with product functionality and performance: for example, the move to address health issues by reducing sodium and sugar results in higher water activity which can promote the growth of microbes. This needs to be compensated for by other production and ingredient solutions.

It’s important to keep in mind that bacteria mutate. Product studies that may have been relevant 10 years ago, are out of date as pathogens like Listeria change and evolve.

To overcome concurrent requirements – and ultimately safeguard their products and businesses — processors can deploy a multi-hurdle antimicrobial protection system.

Similar to the overall multi-hurdle approach to food safety that spans farm to fork, this system for antimicrobials encompasses the sourcing of ingredients and extends through cooking and packaging processes to close gaps in protection and mitigate risks posed by potentially harmful microbes.

The concept of using multiple hurdles to control microbial growth in formulated foods has been used in the food industry for decades,” explains Dr. Kathleen Glass, Distinguished Scientist, Associate Director of the Food Research Institute at the University of Wisconsin-Madison. “Understanding the additive or synergistic effect of moisture, salt, and pH, allows the use of relatively low levels of ingredients with effective growth inhibition properties; in other words, products don’t have to be formulated to extremes of pH, water activity, or antimicrobial levels that might be necessary if using one factor alone. The benefits of using the multiple hurdle approach are that this allows foods to be formulated to achieve desired quality and sensory attributes, control production costs, and provide an additional margin of safety during extended cooling or extended storage.”

Using one solution instead of multiple solutions is not likely to solve all potential issues related to spoilage. Moreover, if a processor uses just one solution, like vinegar (acetic acid), the required amount to reduce food safety risk would be so high that it can lead to a degradation in quality, flavor, and smell. Acetic acid at a lower level and in conjunction with another antimicrobial has shown to provide better protection with lower organoleptic contribution.

Acetic acid and peptide bacteriocins are especially useful in today’s processing and production environments, offering multi-hurdle antimicrobial protection while meeting multiple demands.

Peptide bacteriocins are considered the keys that “unlock” the walls of cells, and inhibit cell wall synthesis. “Peptide bacteriocins are the perfect extra hurdle. Propionic and lactic acids are also synergistic hurdles to acetic acid. Propionic acid is strong on gram-negative bacteria too, which is the reason we recommend it in combination with acetic acid for fresh applications,” explains Philipp Martin, Director of Technical Services at Wenda Ingredients.

The most prevalently used organic acid today is acetic acid, commonly known as vinegar in liquid or dried form. Acetic acid has been widely incorporated into today’s food system but shows limitations due to acidification quality problems surrounding flavor and texture. Less acetic acid (vinegar) can be used when in conjunction with peptide bacteriocins and other organic acids, improving organoleptic and product quality.

Furthermore, ascorbic acid from cherry powder is a powerful antioxidant and potentially one of the most underutilized shelf-life protection ingredients used today. Ascorbic acid, otherwise known as vitamin C and labeled as “cherry powder”, is a potent reduction agent enabling antimicrobials and nitrite to work faster and better. For example, ascorbic acid enables nitrites to work faster to provide naturally-cured color initially and through shelf-life. “Research supports that naturally occurring sources of nitrite have equivalent functionality to pure sodium nitrite for inhibiting the growth of C. perfringens provided a cure accelerator is used and the concentration is equivalent.” (Study: King et al., 2015).

Natural propionic acid is a potent protection ingredient for yeast and mold adding critical support for protecting bakery and liquid products that otherwise would have a much shorter shelf-life. Interestingly, natural lactic acid antimicrobials are effective at controlling a wide range of bacteria including but not limited to lactic acid spoilage bacteria.

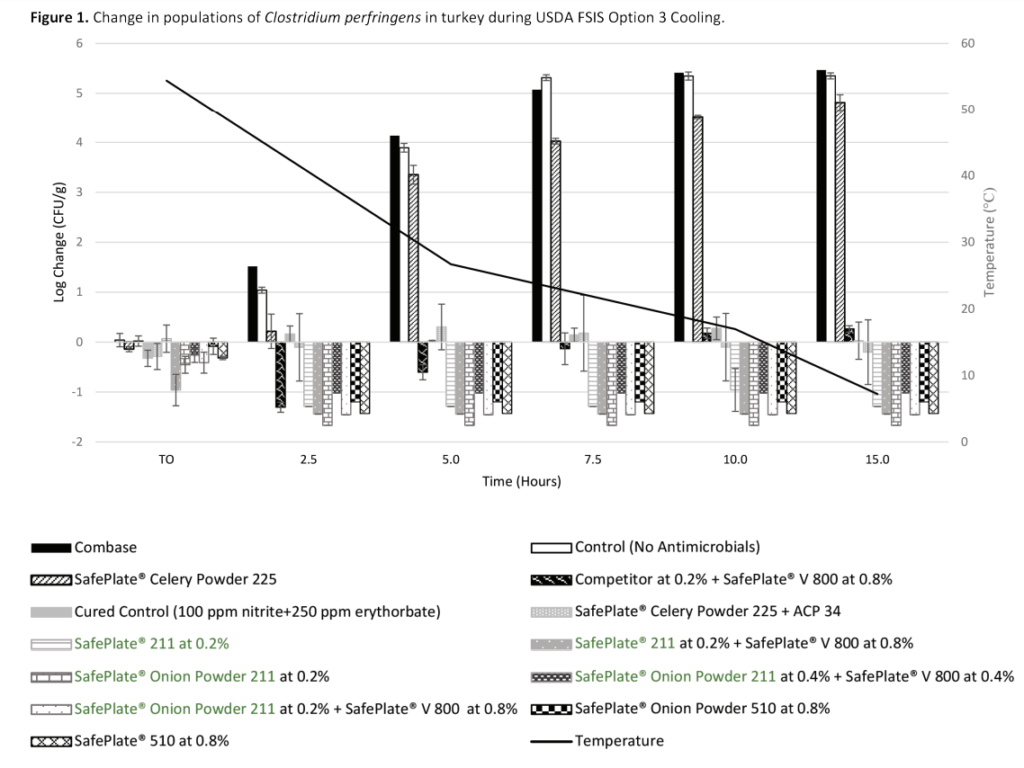

The results of a recent study, Antimicrobial Activity of Clean Label Ingredients: Inhibition of Clostridium perfringens in a Model Meat System, were published by the Food Research Institute at the University of Wisconsin Madison in August 2022. The study examined the effect of various clean label antimicrobials on the inhibition of Clostridium perfringens during extended cooling in a ground turkey product (75% moisture, 1.12% salt and pH 6.3).

Among other results, this study found that the positive growth control consistently supported rapid growth of C. perfringens during the 15‐ hour cooling profile. The turkey formulation containing only SafePlate® Celery Powder 225 (100 ppm nitrite) permitted >4 log increase in growth of C. perfringens, but when combined with Acerola Cherry Powder ACP 34 (250 ppm ascorbic acid) C. perfringens growth was inhibited throughout

the 15-hour cooling period. Furthermore, the most protection provided was from SafePlate® Onion Powder 211, showcasing how peptide bacteriocins are essential for formulators looking to maximize their multi-hurdle antimicrobial protection.

Turkey formulations containing a minimum of the following antimicrobials effectively inhibited the growth of C. perfringens:

Food manufacturers are in the business of developing food products and not developing antimicrobial ingredients. Therefore, food manufacturers rely on their suppliers to identify and develop novel solutions to their food safety concerns that are ready for them to incorporate and validate in their particular formulations,”

– DR. KATHLEEN GLASS,

UNIVERSITY OF WISCONSIN-MADISON

Natural antimicrobial ingredients have advantages over other food safety interventions. For example, high pressure pasteurization (HPP) used to lower the risk of Listeria and spoilage bacteria improve shelf-life but has its own vulnerabilities, due to the cost, time, and limited protection from spores. Ingredients should be used in conjunction with physical and thermal processes for residual product protection in the presence of a leaky bag and during primary and secondary shelf-life once the consumer opens the food product.

“Synthetic antimicrobials have a proven track record for use in various foods. However, manufacturers still need clean label alternatives that have been validated to be effective against multiple microbial targets, have low cost, and have insignificant effects on sensory properties,” points out Dr. Glass, adding, “There is a lack of transparency for what active ingredients are the source of the antimicrobial activity in clean label ingredients. Knowing the class of active compound will help product developers understand limits of use and determine how extensive the challenge studies need to be to validate usefulness.”

Processors using celery powder can boost food safety and cured color easily with vitamin C. Nitrite by itself can provide cured color, but color is maintained and nitrite is a more effective antimicrobial with ascorbic acid as found in cherry powder.

SafePlate® Cultured Onion, consisting of cultured onion juice, increases shelf life and pathogen protection without sacrificing an ultra-clean label. It contains antimicrobial-rich organic acids and peptides capable of inhibiting toxin-producing spores, pathogens and spoilage bacteria. Blends include naturally occurring peptide bacteriocins, acetic, and lactic acids. SafePlate® Cultured Onion has low hygroscopicity with virtually no impact on flavor and is a cost-effective replacement for expensive HPP and other antimicrobials. Available as a powder or liquid, it can be used in products like deli meats, sausages, poultry, sous vide cooked meats and RTE meals, side dishes and meat and poultry. Applications also include meat alternatives, seasoning blends and HPP-processed meat and poultry.

Synergy is key with antimicrobial usage in meat and poultry applications. For example, although processors often use celery powder to cure products, celery powder is not as effective an antimicrobial as when it is used in conjunction with ascorbic acid from cherries. Ascorbic acid with nitrites – such as celery powder paired with cherry powder — are a combination that provides desired cured color, taste, clean labeling and, importantly, protection from bacteria such as Listeria monocytogenes and spores such as Clostridium perfringens and Clostridium botulinum.

For cured and fresh meat products – and for items that are increasingly popular among consumers, such as fresh prepared meals to go, meal kits, shelf-stable products and foods delivered to homes –formulations with synergistic ingredients are crucial in delivering on consumers’ full suite of expectations. Instead of relying on one solution with likely tradeoffs, using secondary ingredients that perform other functions can result in the near perfect eating experience that consumers want and enjoy.